Friday, September 16 2022

Achieve Meaningful Business Results with Industry 4.0 Technologies

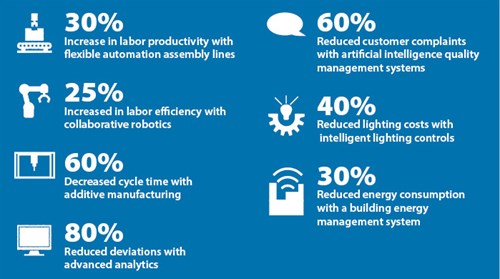

The World Economic Forum’s report “Fourth Industrial Revolution: Beacons of Technology and Innovation in Manufacturing” (WEF report, link opens PDF) cites truly meaningful business results that manufacturers achieve with new technologies.

These include:

Why don’t small and medium-sized manufacturers (SMMs) adopt new technologies more quickly? Studies have uncovered many reasons, but most boil down to a very simple barrier: the lack of time.

Resources are tight and immediate business needs take precedence. You have orders to fill, employees to hire and train, payroll, supply chain disruptions, maintenance and more. Your smaller shop doesn’t have the budget of an original equipment manufacturer. You can’t hire and train more employees as easily as a large operation.

On the flip side, SMMs have fewer layers. You can get input, develop a business case and make decisions faster than a large shop. Smaller manufacturers also don’t have as many information technology layers to deal with when implementing new technology.

The good news is that technology adoption isn’t all or nothing. There are low-cost, easy-to-implement technologies that can drastically increase your productivity.

Want to learn more about Industry 4.0 technologies?

Visit our Digital Manufacturing & Technology Center (DMTC) page to discover all of the ways Purdue MEP can help!