Tuesday, April 25 2017

Competition is no longer between companies but between supply chains. Manufacturers encounter statements like, “A successful company has a supply chain that aligns with the corporate strategy while being flexible and responsive to external pressures”. This may be true, however, the real question is HOW does one design and implement a supply chain that fosters collaboration, reduces waste, and delivers value to the customer?

Those with optimized supply chains experience benefits like:

Lower Costs

Better Delivery

Increased Quality

Competitive Edge

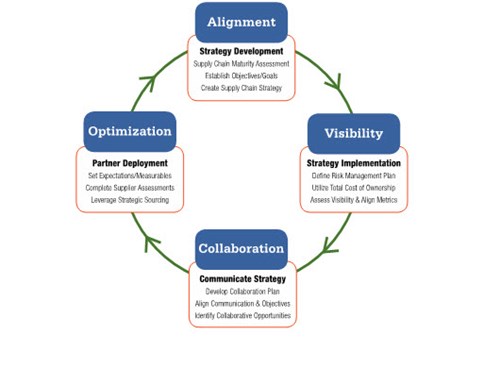

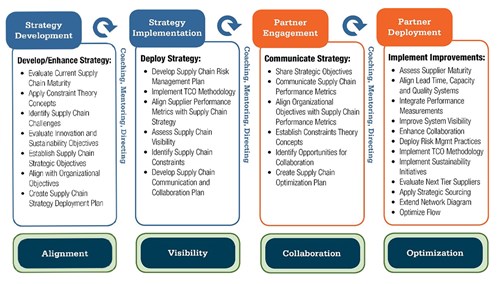

The Purdue Manufacturing Extension Partnership (MEP) offers a Supply Chain Optimization roadmap that covers five critical areas; Alignment, Value, Risk Management, Visibility, and Metrics. Each critical area builds to the next; creating a strategy and implementation plan along the way.

Supply Chain Optimization Strategy

Deployment Strategy

Create a supply chain strategy that aligns with your company’s goals and a solid implementation plan that includes your critical suppliers.

- Supply Chain Maturity Assessment: Begin by assessing the Supply Chain maturity of your organization. MEP uses an Ordered Pair summary to identify opportunities for internal improvement.

- Constraint Theory Application: Educate the team on Constraint Theory, understanding the difference between a “Bottleneck” and a “Constraint”. This is important knowledge for a team to possess. Purdue MEP uses value stream mapping to determine the critical supply chain path which will be analyzed during the visibility stage.

- Create Supply Chain Strategy Deployment Plan: Establish a strategic plan with clear understandable performance objectives and identify supply chain challenges. Purdue MEP uses the Five Bold Steps tool to determine which goals to pursue and the specific actions required to achieve these goals.

Internal Strategy Implementation

Visibility is key to a sustainable supply chain strategy. Now that the strategy is known, it is time to identify critical suppliers, risks, and costs within the supply chain.

- Assess Supply Chain Visibility: The more visibility into and collaboration with suppliers, the more likely one will increase overall performance, address system constraints, and mitigate risks. Purdue MEP uses value stream mapping to identify critical suppliers within your supply base based on the theory of constraints.

- Risk Management: Identify potential Supply Chain risks using Purdue MEP’s risk management tool in a one-day workshop. This list becomes the core set of risks to use in the development of a Risk Management Plan.

- Implement a Total Cost of Ownership (TCO) Methodology to support strategic sourcing decisions during Purdue MEP’s one-day workshop that provides the TCO calculator.

- Develop Supply Chain Communication and Collaboration Plan to ensure suppliers understand expectations and are aligned with the company’s goals by establishing key metrics.

Partner Strategy Collaboration

After defining a clear supply chain strategy with key metrics, it is time to collaborate with suppliers who are part of the critical path. In a one-day supplier session, the following should be communicated:

- Share Strategic Objectives: immediate, midterm, and long-term

- Communicate Supply Chain Performance Metrics and the reasons behind them…align with company’s goals

- Discuss capacity requirements while educating them on Constraints Theory concepts

Further collaboration with each critical supplier entails:

- On-site visit to supplier’s facility to assess current state and establish goals/metrics for improvement, as needed

- Identify Opportunities for Collaboration

Partner Strategy Implementation

Once partner expectations are established and understood, it is time to implement a strategic plan for each partner throughout the supply chain critical path. The company's partners should go through the same steps above to establish and then implement their own supply chain strategy; keeping in mind that it should align with their partners’ goals.

- Assess Supplier Maturity

- Align Lead Time & Capacity

- Improve System Visibility

- Enhance Collaboration

- Deploy Risk Management Practices

- Implement TCO Methodology

- Evaluate Next Tier Suppliers

- Extend Network Diagram to the next tier

Need help? Reach out to a Purdue MEP with any questions at mepsupport@purdue.edu.

-OR- Sign up for one of our workshops on Total Cost of Ownership, Risk Management, and many others!