Tuesday, January 03 2017

Are You Missing Money in your Water Bills?

Here in Indiana, water often gets overlooked when searching for continuous improvement projects and cost cutting measures. Water is cheap in Indiana, right? In 2017, we understand better than ever the truth behind our water costs.

Today, we realize that there is more to water than what comes on your water bills. In reality, there are hidden costs to water throughout your facility.

- Does your water get heated up?

- Do you use steam?

- Does water get moved around within your plant?

- Do you use water in your actual production processes?

- Do you have a Reverse Osmosis system?

- Do you have a cooling tower?

- Does any of your water/steam infrastructure require frequent maintenance?

- If your local water source became contaminated or shut down temporarily, would it impact your plant’s production?

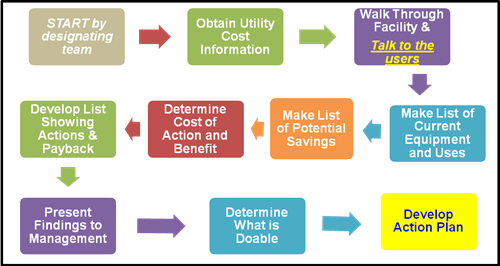

If the answer is, “Yes,” to more than one of these, then you should be exploring cost savings opportunities. You can start saving money today by following this basic water audit process below, or hiring an experienced sustainability consultant to walk you through this process and help identify some common mistakes in water usage.

Diagram from the State of California’s Task Force Water Use Best Management Practices Report

Water conservation strategies prior to 1990 tended to focus solely on basic water reuse and recirculation. Since then, we’ve seen an influx of high efficiency spray nozzles, better clean-up procedures, and improved controls.

Hoosier manufacturer Cummins has taken this bull by the horns. In 2011, Cummins developed a comprehensive water management strategy, and has been internationally recognized as a leader in their efforts. On the company website, they share that:

Cummins’ risk mitigation tool takes into account costs such as pumping, heating and chemical usage in water, which are often not considered when evaluating a project. In addition, the company’s risk assessment tool assesses water conservation and efficiency at a site as well as risk exposure and other factors.

Cummins developed aggressive targets, establishing a water conservation goal of 33% (labor normalized reduction to a 2010 baseline). As of the end of 2015, a 41% reduction was achieved, exceeding their original goal.

How did they achieve their goal? One example is installing an experimental $28,000 water purification system, which is producing annual savings of $85,000. This system is based a new silica-based technology that prevents water quality from deteriorating quickly to the point that it damages pipes and equipment. The new system allows the water to cycle 180 times, said Phil S. DeVinney, facility manager at the Fuel Systems Plant. They have since expanded this technology to other locations, and expect that as this grows globally, it will save them billions of dollars annually.

The options for improving & reducing your water costs are varied. Some measures are universal, but many are specific to your industry. There are fantastic resources and extensive lists of Best Management Practices now available to you, including resources like the Alliance for Water Efficiency, and your local Manufacturing Extension Partnership.